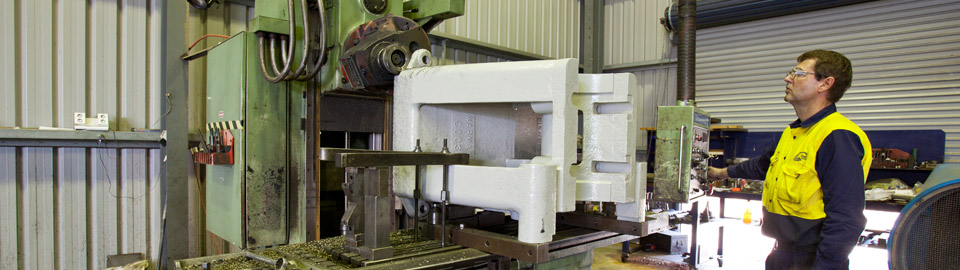

Remote and Workshop Line Boring

Our mobile machining/ Line boring department has two Hofmann line boring units, both of which are fully mine site compliant. Our mobile line boring units are often seen at BHP Cannington mine, Xstrata MIM and Ernest Henry mines, Aditya Birla Mount Gordon mine and Eloise mine.

Unit number one is set up in a purpose built 4×4 truck that can travel to remote work sites for long durations to tackle the most demanding of tasks.

The second unit is a more versatile cartridge mounted unit for transport to more difficult locations- confined workshop spaces, underground sites etc.

This unit can also be operated still mounted on the back of the transport vehicle and does not have to be removed at site if required.

Works undertaken in the past include:

- Various excavators from Komatsu, CAT and Hitachi up to the 996 Liebherr excavators and face shovels- Repairs to bores on the boom, stick and bucket as well as the bucket control tri-links and dog bones

- Graders of various sizes and ages- articulation bores, grader circle mounting bore, front axle oscillation bores and repairs to steering cylinder mount bores.

- 775D through to 793D CAT and HD465 up to 830E Komatsu Off highway dump trucks- Tray pivot bores, rear differential dog bone link bores, suspension strut bores, A-frame pivot bores and more.

- Wheel loaders from CAT, Komatsu, Volvo etc from the smallest up to the CAT 994 loader- articulation bores, steering cylinder mount bores, all boom and bucket bores.

- Various cylinder mount and articulation bores on drill rigs both the surface and the underground units including Sandvik Axera, Atlas Copco and Boart Longyear.

- CAT/ Elphinstone R1300G – R2900G and Toro T010 – Toro T11 Underground load haul dump (Mucking) units- articulation bores, steering cylinder mount bores, all boom and bucket bores.

- Underground dump and ejector tray trucks including CAT, Elphinstone, Atlas Copco and Sandvik Toro- Tray pivot, steer cylinder mount, articulation and hoist cylinder bore repairs.

- Underground utility vehicles including Getman and Normet/ Mulimec unit- articulation hitches, front axle oscillation cradle mounts and work on a wide range of attachments for these vehicles.

- Various fixed plant repairs include works on underground piston displacement dewatering pumps, crushers of different sizes, flask doors, zinc filter presses, ore skip bins etc.

These are a few of the tasks we can accomplish with 24 hour operations ( 2 operators on 12 hour shifts) if required to keep down time to a minimum.

To discuss your line boring needs, contact Stephen Byrnes 0438 563 589